What Reaction Best Describes Preparation of Rubber

Finally dry the substrate in hot air. Rubber is obtained by coagulation of the latex by adding dilute acid.

Vulcanization Process An Overview Sciencedirect Topics

Which statement best describes rubber cup polishing.

. The 3 most common durometer gauges used to measure rubber are Type A Type M and Type D. It is a polymer of 2-methyl 13-butadiene or isoprene. Since dichlorodimethylsilane is bifunctional has two chlorines the chain is able to propagate in two directions generating high molecular weight polymers which retain some residual hydroxyl groups.

Polymers that are rubber-like solids and having elastic properties. Polymer is a large molecule composed of repeating structural units connected by covalent bonds. Precuring of the adhesive or rubber before the rubber comes in contact with the adhesive.

An average plant will produce about 19 pounds of latex annually. Rubber compounding with carbon particles often involves intensive mechanical processing and both components are susceptible to grafting reactions. The reaction with sodium.

It is made up of a thick stretchy white liquid which is latex and some suspended solid particles. The first step is the preparation of sodium polysulfide by the reaction of sulfur S8 with a strong base sodium hydroxide NaOH. Material loss due to abrasion can be measured with various instruments according to tests such as ASTM D394.

Butyl rubber is produced by copolymerizing isobutylene in solution with low concentration of isopreneIsobutylene is refrigerated to very low temperature and is diluted with methyl chlorideReaction initiates on addition of low concentration of isoprene in the presence of aluminium chloride and as a result compounds copolymerizesIn copolymerization single unit. A direct antiglobulin test on a blood sample was positive. The Small-Scale Preparation of Thiokol Rubber This preparation of Thiokol rubber is a two-step process.

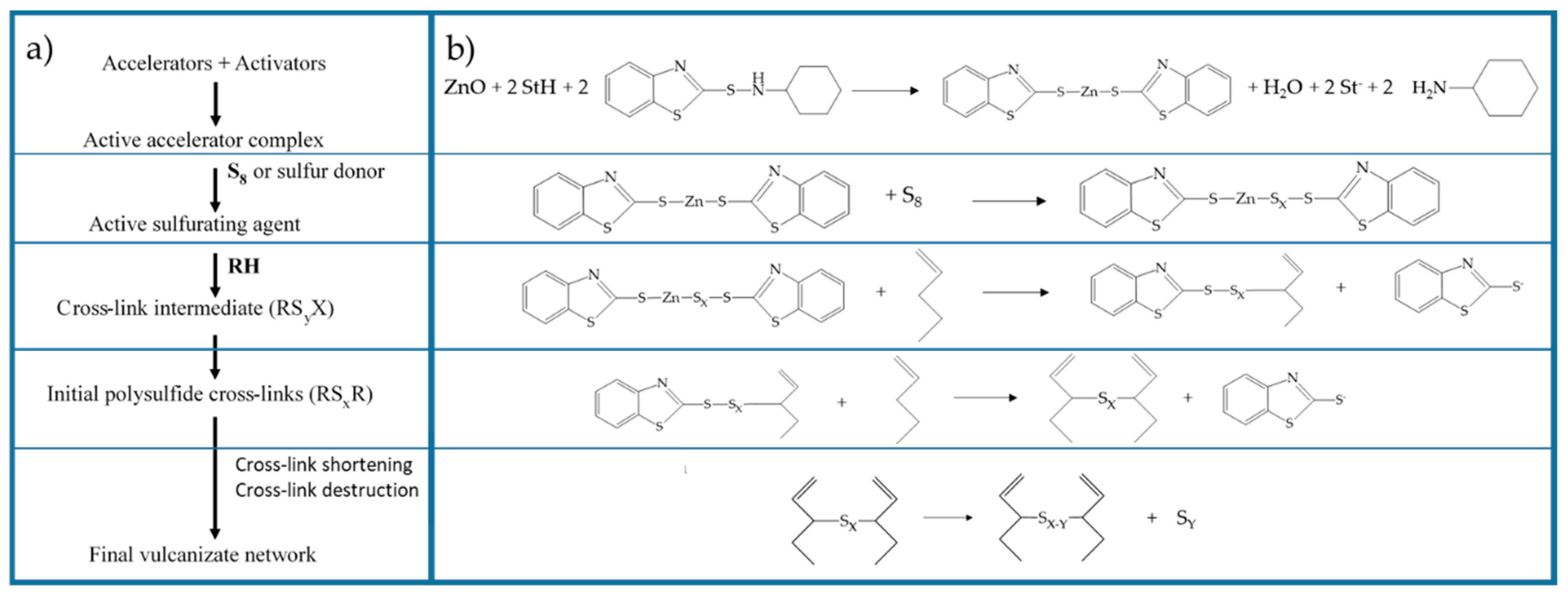

Natural rubber latex NRL has been used in cold-seal adhesive formulations for over 100 years. Anadolu Üniversitesi Bilim ve Teknoloji Dergisi A-Uygulamalı Bilimler. Vulcanized Rubber Sulphur is used in cross bonding the polymer chains found in natural rubber Cellulose acetate rayon etc.

As heated stick compound is not used for retainer stabilization minor adjustments if required of the retainer can be performed. C Synthetic rubber has different monomers than natural rubber. Copolymer a polymer made from more than one kind of monomer.

The coagulated latex is washed dried and passed through rollers to get sheets of natural rubber. Abrasion resistance describes a rubbers resistance to being worn away from rubbing or scraping. Inadequate cement film thickness.

The rubber dam frame is then placed on the dam. Following that rinse it in cold DI water followed by a rinse in hot DI water. With adequate rubber dam isolation cavity preparation caries excavation can be verified using caries disclosing dye is completed.

The initial hydrolysis reaction exothermically generates a silanol SiCH 3 2 OH 2 which readily condenses through loss of water to form the siloxane polymer. Then it is processed for common use by various methods. Rubber is an elastomerthat is a polymer that has the ability to regain its original shape after being deformed.

1Helps strengthen decalcified enamel 2Removes some of the fluoride-rich layer of enamel 3Is used to remove small bits of calculus after scaling 4Should be used on every patient at his or her recall. Low molding pressure or temperature. Liquefies between 71-100 degree centigrade B.

Natural rubber is a plant polymer we harvest it from rubber plants in the form of Latex. The term cold seal describes an adhesive that bonds to itself under pressure at ambient temperature without adhering to other materials. The mechanochemical reactions induced by mechanical energy imparted to elastomer molecules have been used since Hancock discovered the effects of mastication that is the mechanochemical degradation of a polymer.

Type M also for soft materials was developed to test small specimens typically O-rings that do not meet the physical size requirements specified. The table below lists the chemical treatments typically used for some most commonly used rubber substrates. Rubber is also tough and resistant to weathering and chemical attack.

The latex obtained from rubber trees is a suspension of small rubber globules in water and has the appearance of milk. In this reaction elimination of some small molecules like water and hydrogen chloride etc will take place. In general natural rubber is very sticky in nature.

Natural rubbers are also known as elastomers hydrocarbon polymer due to its high elasticity. Hello In this case since statements A and B are correct due to the abundance of natural rubber and that both of them have the same properties making then suitable for several applications specially in the production of tires belts hoses footwear and others chemically. S8 2 NaOH Na2S8 At room conditions sulfur is normally in the form of S8 rings and chains.

However the rubber industry is a highly mature and complex sector with over twenty-five 25 different generic types of rubber natural rubber styrene-butadiene rubber nitrile ethylene. Rubber-Cement RC Failures Separation between rubber and cement is usually characterized by a relatively glossy hard surface on the metal with little or no rubber visible. Following preparation a fluoride.

Reaction of natural rubber with sulfur molecule S 8 in presence of heat to improve its properties is called vulcanization of rubber. Vulcanization of Rubber. The result is a product that is stronger more elastic more resilient and less sensitive to temperature changes and the action of solvents than the original.

Chain lengthening Which of the following is true about agar hydrocolloid impression material. This rubber is slightly inferior to natural rubber in its physical properties. These polymers formed by chemical reaction in a controlled environment and are of commercial importance.

Common causes of RC failure are. Vulcanization is a chemical reaction between rubber and a functional group usually brought about by heat. Here the polymer bonds are held together.

Learn different types of Polymerization here. Elastomers can be naturally occurring polymers such as natural rubber or they can be synthetically produced substances such as butyl rubber Thiokol. It is prepared by copolymerisation of 13 butadiene and styrene along with sodium.

Natural rubber or rubber latex is directly collected from plants. The latex consists of 30-3 per cent of the rubber hydrocarbon. 2 Classification Based on Structure of Polymers.

Natural rubber is a polyisoprene produced by Hevea trees that consists of approximately 99 cis-14 repeating units. They are again classified into four subgroups. Which of the following statements best describes this reaction-The antibody present reacted best at room temperature-The patient had IgM antibody to the red cells transfused-Only IgE was coating the transfused red blood cells-The patients reaction was the result of an amnestic.

Type A is used to test soft rubber materials while Type D is used to test hard rubber and plastic materials. Terylene and Nylon 66 are examples. In industrial applications abrasion-resistant rubber is used with conveyor belts that move coal and in pumps that handle slurries.

Based on Forces Between Molecules. The process of changing the rubber base product or liquid polymer to a rubber like material is generally known as. Download Table EPDM rubber mixture preparation procedures from publication.

It is used for making tyres and conveyor belts. Cheremisinoff PhD in Condensed Encyclopedia of Polymer Engineering Terms 2001 VULCANIZING AGENTS. Immerse the rubber substrate in concentrated sulfuric acid for 2-10 minutes.

Solidifies between 50-70 degree centigrade.

![]()

Silicone Rubber Platinum Based Catalysts Simtec

Forms Of Energy Interactive Science Notebook Energy Forms Interactive Science

Rubber Tubing What Is It How Is It Made Types Materials

Physical Decoloration In The Concentration Process Of Natural Rubber Rojruthai 2021 Spe Polymers Wiley Online Library

How Latex Is Made Material Production Process Making History Used Processing Components Composition

Synthetic Rubber An Overview Sciencedirect Topics

Rubber Tapping And Coagulation Britannica

Rubber Tubing What Is It How Is It Made Types Materials

Styrene Butadiene Rubber Chemical Compound Britannica

![]()

Silicone Rubber Types Uses Properties Applications

Catalysts Free Full Text Zinc Based Curing Activators New Trends For Reducing Zinc Content In Rubber Vulcanization Process Html

Styrene Butadiene Sbr Rubber Uses Structure Material Properties

Polyisoprene Rubber An Overview Sciencedirect Topics

Synthetic Rubbers Synthetic Fibres Youtube

Thermal Stability Of Carbonates Of Group 1 And 2 Chemistry Notes Chemistry Dow

Comments

Post a Comment